Minotaur IV Launch Vehicle

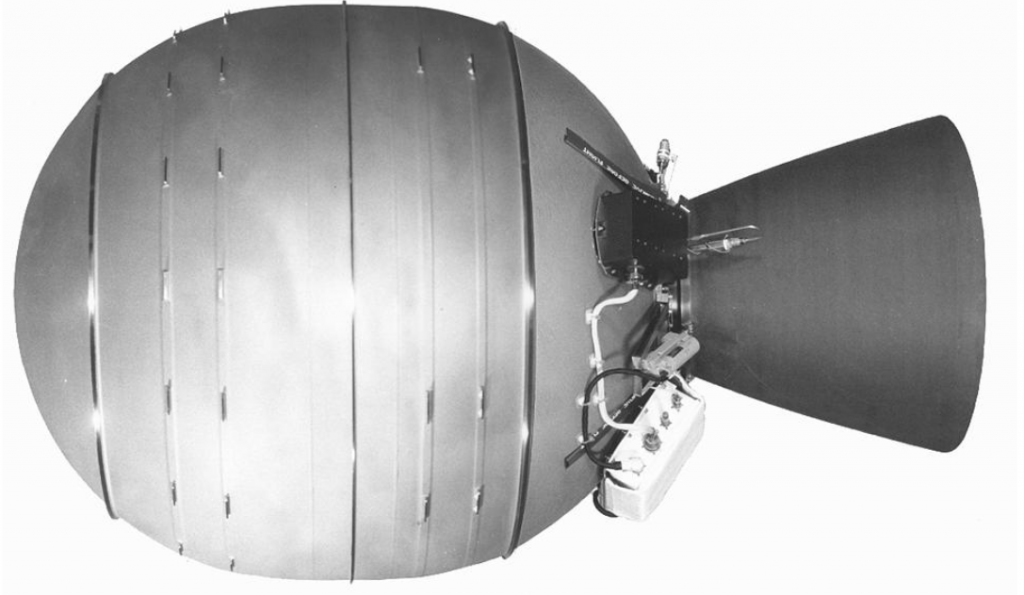

Minotaur IV, also known as Peacekeeper SLV, is an expendable launch system operated by Orbital ATK under the Orbital Suborbital Program 3 of the U.S. Air Force under which surplus Minuteman and Peacekeeper Intercontinental Ballistic Missile stages are combined with commercial upper stages to create cost-effective launch solutions for the U.S. Government. The baseline Minotaur IV design builds the foundation for a family of launch vehicles optimized to serve on sub-orbital, Low Earth Orbit, Geostationary Transfer Orbit and Lunar Transfer missions.

The broader Minotaur family comprises the Minotaur I orbital launch vehicle based on Minuteman II stages, Minotaur I Light for sub-orbital missions, Minotaur II as a Minuteman-based sub-orbital target launch vehicle, Minotaur III as a Peacekeeper-based sub-orbital target delivery system and the also Peacekeeper-based Minotaur IV family which itself consists of five members: Minotaur IV / IV+ for orbital launches (typically to LEO), Minotaur IV Light for sub-orbital/target application, Minotaur V for high-energy missions to Medium or Geostationary-Transfer Orbit and Lunar Transfer Orbits, and Minotaur VI / VI+ for all orbital regimes.

Minotaur launch vehicles are available for any government-sponsored mission with the goal of providing a highly reliable solution that is more cost-effective than purely commercial launch vehicles.

The Minotaur launchers operate under the philosophy of coupling government-furnished Minuteman/Peacekeeper stages with flight-proven, commercial upper stages either using solid or liquid fuels. Minotaur IV features three Peacekeeper stages, designated SR-118, ST-119 and SR-120 with an Orion 38 (IV) or Star 48BV (IV+) fourth stage plus an optional HAPS upper stage for precise injection capability.

The Minotaur IV Light version features the three Peacekeeper stages and HAPS to create a capability for precise sub-orbital deliveries. Minotaur V is a five-stage vehicle with a Star 48BV and Star 37 sitting atop the Peacekeeper stack to create a vehicle suitable for high-energy orbital deliveries as well as trans-lunar missions. Minotaur VI is a six-stage vehicle that uses the Minotaur V stack plus an additional SR-118 boost stage.

The Minotaur IV family provides a reliable and flexible means of placing satellites into orbit. Flexibility is provided by the different vehicle versions that can be catered to a mission’s specific performance needs as well as the ability of operating Minotaur from all major U.S. space launch sites via transportable Launch Support Equipment to cover the entire spectrum of orbits. Minotaur is operated from the Kodiak, Wallops, Vandenberg and Cape Canaveral ranges – taking advantage of existing range infrastructure while not necessarily requiring permanent launch pads.

As of July 2017, the Minotaur rocket family completed 25 missions of which ten were sub-orbital. The Minotaur IV flew for the first time in 2010 on a sub-orbital mission with DARPA’s Hypersonic Test Vehicle 2a. Also in 2010, Minotaur IV flew two orbital missions with the SBSS space surveillance satellite and the STP-S26 multi-payload launch followed by another two missions in 2011 with HTV-2b delivered to a sub-orbital arc and TacSat-4 racing into orbit atop the first Minotaur IV+ vehicle. Minotaur V flew for the first and only time to date in 2013 with the LADEE lunar exploration mission for NASA.

An illustration of Minotaur’s flexibility is a 2017 launch of a modified Minotaur IV rocket with the ORS-5 / SensorSat mission that requires a direct injection into an equatorial orbit 600 Kilometers in altitude with zero inclination. The inclination change in particular requires a significant change in velocity for which the standard Minotaur IV stack is fitted with an additional Orion 38 stage that will accomplish the circularization from a Low Earth Parking Orbit and the much larger inclination change to deliver the satellite to its target orbit.

Peacekeeper was a land-based ICBM that entered development in 1972 to expand the U.S. arsenal in response to Soviet missiles which could have put them into an advantageous position. Development of the R-36M missile by the Soviets gave the Soviet Union the theoretical ability to destroy the US Minuteman ICBM facilities before retaliation would have been possible. This prompted the development of the Peacekeeper launcher that could also deliver warheads to orbit via a Post Boost Vehicle and Deployment Module to independently target the individual warheads.

The first test launch of the Peacekeeper took place in 1983 from Vandenberg Air Force Base in California and the system was deployed in 1986. In 2003, the retirement process for the Peacekeeper was started and by September 2005, the last Peacekeeper was removed from alert status. Peacekeeper warheads are being deployed on Minuteman III missiles which currently is the only land-based ICBM in use by the United States.

.

Minotaur IV Specifications

| Type | Minotaur IV |

| Launch Site | CCAFS, Vandenberg, Kodiak, MARS |

| Height | 23.88 m |

| Diameter | 2.34m |

| Launch Mass | 86,300 kg |

| Stages | 4 (+ Optional Upper Stage) |

| Stage 1 | SR-118 |

| Stage 2 | SR-119 |

| Stage 3 | SR-120 |

| Stage 4 | Orion 38 (Star 48BV Optional) |

| Stage 5 | Orion 38 or HAPS (Optional) |

| Mass to LEO | 1,591 kg (IV); 1,837 kg (IV+) |

| Mass to MTO | 650 kg |

| Mass to GTO | 532 kg |

| Mass to TLI | 342 kg |

The Minotaur IV launch vehicle, typically flying in a four-stage configuration with optional liquid-fueled upper stage for precise injection, stands 23.88 meters tall and measures 2.34 meters in diameter with a launch mass of 86,300 Kilograms. Minotaur IV is an inertially-guided launch vehicle built on the design philosophy of conservative design margins, state of the art structures, modular avionics and a streamlined integration and test campaign leading up to launch.

The first three stages of the vehicle are government-furnished Peacekeeper stages that are used as provided by the government, requiring no modification. All three are large solid-propellant motors and feature vectorable nozzles for three axis control during propulsive flight with all three stages typically firing in close succession before handing off to the commercial upper stage. The SR-118 first stage delivers 2,224kN of thrust over a 56.5-second burn; the SR-119 second stage features an extendable exit cone for optimized operation in vacuum and delivers 1,223kN of thrust over 61 seconds and the SR-120 third stage, also with extendable nozzle, generates 289kN of thrust for 72 seconds.

After operation of the first three stages is typically a coast phase of varying duration to set up for orbit injection by the also solid-fueled Orion 38 or Star 48 third stage while the optional HAPS would be used for orbit optimization on missions requiring precise injection capability.

Minotaur IV – in its basic configuration (SR-118, 119, 120 and Orion 38) – can deliver 1,591 Kilograms into a 200-Kilometer, 28.5° Low Earth Reference Orbit. The IV+ version with Star 48BV instead of Orion 38 can lift 1,837 Kilograms into the same orbit. Polar Orbit capabilities for the two versions are 1,170 and 1,430 Kilograms, respectively.

First & Second Stage.

| First Stage | |

| Type | SR-118 (TU-903) |

| Diameter | 2.34m |

| Length | 8.4m |

| Propellant | Solid – HTPB |

| Launch Mass | 49,000kg |

| Empty Mass | 3,600kg |

| Propellant Mass | 45,400kg |

| Guidance | via Booster Control Module |

| Propulsion | TU-903 |

| Thrust | 2,224kN |

| Burn Time | 56.5sec |

| Specific Impulse | 229sec (SL), 284sec (Vac) |

| Control | Hydraulic Thrust Vector Control |

| Second Stage | |

| Type | SR-119 |

| Diameter | 2.34m |

| Length | 7.9m |

| Propellant | Solid – HTPB |

| Launch Mass | 27,700kg |

| Empty Mass | 3,200kg |

| Propellant Mass | 24,500kg |

| Engine | With extendable Exit Cone |

| Guidance | via Booster Control Module |

| Thrust | 1,223kN |

| Burn Time | 61sec |

| Specific Impulse | 308sec (Vac) |

| Control | Hydraulic Thrust Vector Control |

Minotaur IV uses, as its first three stages, government-furnished Peacekeeper stages that require no modification for integration and interface with the vehicle’s modular avionics designed to comply with the unmodified stages. The SR-118 solid rocket motor was manufactured by Thiokol and is also known as TU-903 and uses HTPB (Hydroxyl-terminated polybutadiene) based propellants. The first stage is loaded with 45,400kg of propellant that is consumed during the 56.5-second burn of the stage to provide 2,224 Kilonewtons of thrust (226,780 Kilograms).

Control during first stage flight is provided by a hydraulic Thrust Vector Control System steered with actuator commands provided by the Booster Control Module that links the flight computer to the TVC system.

The second Stage of the Minotaur launcher was manufactured by Aerojet and also uses HTPB-based propellant. It is 2.34 by 7.9 meters in size with a launch mass of 27,700 Kilograms. It closely resembles the design of the first stage and also uses a hydraulic Thrust Vector Control System that provides attitude control during the 61-second burn of the second stage. It provides a thrust of 1,223 Kilonewtons (124,710 Kilograms).

Third Stage

| Type | SR-120 |

| Diameter | 2.34m |

| Length | 2.44m |

| Propellant | Solid – NEPE |

| Launch Mass | 7,720kg |

| Empty Mass | 650kg |

| Propellant Mass | 7,080kg |

| Engine | With extendable Exit Cone |

| Guidance | via Booster Control Module |

| Thrust | 289kN |

| Burn Time | 72sec |

| Specific Impulse | 300sec (Vac) |

| Control | Hydraulic Thrust Vector Control |

The SR-120 served as third stage of the Peacekeeper and is also used as the Minotaur third stage.

SR-120 was manufactured by Hercules and uses NEPE propellant containing HMX with greater energy than ammonium perchlorate that is used in most composite HTPB propellants. Propellants containing HMX are not used on commercial launchers because of its explosive hazards, but as a converted ballistic missile, Minotaur uses the unmodified SR-120 with NEPE propellant.

SR-120 is 2.34 meters in diameter, 2.44 meters long and has a total mass of 7,700 Kilograms. It burns for 72 seconds and provides 289kN of thrust (29,470 Kilograms). It also uses a hydraulic thrust vector control system to provide attitude control during its burn.

After the third stage burn, the Minotaur usually performs a coast phase to reach higher altitudes so that the following upper stage burns can serve as circularization maneuvers and raise the perigee of the sub-orbital trajectory to achieve orbit.

Orion 38

| Type | Orion 38 |

| Diameter | 0.97m |

| Length | 1.34m |

| Inert Mass | 102.1kg |

| Launch Mass | 872.7kg |

| Propellant | Solid QDL-1 (HTPB) |

| Propellant Mass | 770.2kg |

| Guidance | Closed Loop PEG |

| Max Thrust | 36.93kN |

| Avg Thrust | 32.70kN |

| Impulse | 287s |

| Nozzle Diameter | 52.6 cm |

| Burn Time | 66.8s |

| Average Pressure | 45.5bar |

| Attitude control | Electromechanical TVC +/-5° |

| Cold Gas Reaction Control System |

The standard Minotaur IV fourth stage is Orion 38, a commercial solid rocket motor of Orbital ATK. For typical missions, Orion 38 is in charge of injection the payload into orbit, typically completing a circular injection via energy management.

Orion 38 is a low-cost, high-performance upper stage that finds applications on the Pegasus, Taurus and Minotaur families. It is 1.34 meters in length and 0.97 meters in diameter with a launch mass of 873 Kilograms.

The Orion 38 holds 770 Kilograms of HTPB-based propellant within a composite engine casing, operating at a pressure of 45.5 bar to create an average thrust of 32.7 Kilonewtons, peaking at 36.9 Kilonewtons.

It also uses an electromechanical Thrust Vector Control System to gimbal the engine nozzle by up to 5 degrees for pitch and yaw control.

Roll control during burns and attitude control during coast phases and for spacecraft separation is provided by a Nitrogen Cold Gas Attitude Control System.

The fourth stage has a burn time of 66.8 seconds that is followed by a coast phase and re-orientation for spacecraft separation.

Star 48BV

| Type | Star 48BV |

| Launch Mass | 2,164.5kg |

| Diameter | 1.24m |

| Length | 2.08m |

| Propellant | TP-H-3340 |

| Propellant Mass | 2,010.0kg |

| Casing Mass | 58.3kg |

| Case Material | Titanium |

| Nozzle Mass | 52.6kg |

| Avg Thrust | 68.6kN |

| Max Thrust | 77.8kN |

| Isp | 288s |

| Throat Diameter | 0.1011m |

| Nozzle Diameter | 0.7475m |

| Chamber Pressure | 39.9bar (Avg) – 42.6bar (Max) |

| Expansion Ratio | 54.8 |

| Burn Time | 84.1s |

| Ignition Delay | 0.100s |

| Attitude Control | TVC +/-4° |

| Roll ACS |

The Minotaur IV+ configuration replaces the Orion 38 third stage with a Star-48 Solid Rocket Motor built by Orbital ATK. The Star 48BV is a solid-propellant upper stage that uses the flight proven Star 48B and adds Thrust Vector Capability (V).

Star 48 was introduced in 1982 and has been used on a variety of spacecraft. Star 48B was spin stabilized and had smaller a performance than the TVC capable version.

The upper stage features a 1.24-meter diameter titanium casing holding a total of 2,010 Kilograms of solid propellant.

It is 2.08 meters in length and has a launch mass of 2,165 Kilograms. It operates at an average thrust of 68.6 Kilonewtons (6,995kg) with peak thrust reaching 77.8kN (7,930kg).

Star-48BV features the longer of two available nozzles for the conventional Star 48. The upper stage features an electromechanically actuated flexseal nozzle Thrust Vector Control System with a maximum nozzle gimbal of four degrees. Star-48 burns for 84 seconds.

Star 48BV is the final stage of the Minotaur IV+ launcher and is capable of relatively precise insertions. On the Minotaur V, an additional fifth stage is installed to improve performance for highly elliptical and trans-lunar trajectories.

Optional 5th Stage – HAPS

| Type | HAPS |

| Diameter | 0.97m |

| Length | 0.30m |

| Propellant | Hydrazine |

| Propellant Mass | 72kg |

| Propulsion | 3 x MR-107 |

| Catalyst | LCH227/202 |

| MR-107 Thrust | 109 – 296N (222N nominal) |

| Mass | 740g |

| Length | 22cm |

| Diameter | 6.6cm |

| Prop Feed Pressure | 8.2 – 27.8bar |

| Chamber Pressure | 4.2 – 11.2bar |

| Specific Impulse | 229 – 232kg |

| Flow Rate | 49 – 131 g/s |

| Expansion Ratio | 20.7 |

| Burn Time | 131 + 110s (2 Burns) |

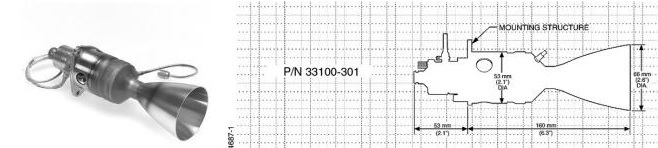

| Attitude Control | Cold Gas RCS (N2) |

Minotaur IV can be outfitted with a HAPS (Hydrazine Auxiliary Propulsion System) to act as fifth stage for precise injections. It is a compact structure with a diameter of 97 centimeters and a length of about 0.3 meters. It is equipped with two spherical tanks holding Hydrazine monopropellant. Each tank holds 36 Kilograms of propellant. HAPS is equipped with a total of three MR-107N thrusters (Super HAPS uses 12 engines). Each of these engines provides a nominal thrust of 222 Newtons with a throttle capability of 109 to 296 Newtons. With the three engines at nominal throttle, HAPS has a total thrust of 666 Newtons – 68 Kilogram-force.

MR-107N operates at a propellant feed pressure of 8.2 to 27.8 bar and a chamber pressure of 4.2 to 11.2 bar to create a specific impulse of 229 to 232 seconds. The engine ingests 49 to 131 grams of fuel per second depending on the thrust setting. It has a expansion ratio of 20.7. MR-107N weighs 740 grams, measuring 22 centimeters in length and 6.6 centimeters in diameter. It uses a Moog Single Seat Valve.

Usually, HAPS performs two burns that are separated by a coast phase of about half an orbit to allow HAPS to perform a precise insertion and refine the vehicle’s orbit to match the target parameters.

HAPS is equipped with a Cold Gas Attitude Control System for three-axis control. Differential firings of the three engines can also be used for attitude maneuvers during propulsive flight phases.

Payload Fairing

| Type | Minotaur IV Fairing |

| Diameter | 2.34m |

| Length | 6.4m (Standard) |

| Mass | 450kg |

| Separation | Ordnance, Frangible Joints,Pistons |

| Construction | Graphite/Epoxy Face Sheets |

| Aluminum Honeycomb Core | |

| Notes | Protects Payload & 5th Stage |

Minotaur IV uses the standard payload fairing that is also used on the Minotaur IV+, V and VI launcher. It is about 6.4 meters long and 2.34 meters in diameter weighing approximately 450 Kilograms. It consists of two composite shell halves, a low-shock frangible rail and ring separation system, and an actuator/hinge fairing jettison system. The fairing structure is a aluminum honeycomb core covered by layers of graphic epoxy composite. The fairing is outfitted with acoustic blankets, a ventilation system and RF windows if required. The fairing also provides access doors to the payloads.

The two fairing halves are joined by a frangible rail joint and the PLF is connected to the second stage using a ring-shaped frangible joint.

A cold gas initiation system is used to disconnect the ring and rail so that the two halves of the fairing can rotate outboard on two hinges installed on the vehicle in order to ensure the appropriate clearances during the separation event.

The payload envelope for the Minotaur V is defined by the Star 37 upper stage because it and its support structure has to fit under the fairing together with the spacecraft.

To accommodate larger payloads, Minotaur can be outfitted with a 2.79-meter diameter fairing that features a similar design, but comes at the cost of launch vehicle performance.

Payload Adapters

Minotaur can support a number of Payload Adapter Modules including off-the-shelf adapters and custom built devices. Payload Adapters interface with the launch vehicle and the payload and are the only attachment point of the payload on the Launcher. They provide equipment needed for spacecraft separation and connections for communications between the Upper Stage and the Payload.

A typical PAM consists of a Payload Adapter Fitting that is connected to the upper stage, a payload cone and a separation system. Minotaur can facilitate Orbital-built as well as Planetary Systems and RUAG Space payload attach systems.

Avionics & Guidance System

Minotaur IV implements a Common Avionics Assembly that is used across the Minotaur family. The CAA is a ring structure that is mounted on the upper stage of the vehicle offering space for the various avionics boxes that comprise the assembly.

The Central Flight Computer of the Minotaur is based on Orbital’ s Modular Avionics Control Hardware (MACH) that provides power transfer, data acquisition, booster interfaces, and ordnance initiation. Up to 10 MACH devices can be combined to satisfy mission requirements. Minotaur’ flight computer uses a 32-bit multiprocessor architecture and a RS-422 serial bus for data connections to avionics and payload systems.

Additionally, the avionics assembly includes the Booster MACH, the Booster Control Module that provides actuator commands to the Thrust Vector Control Systems of the lower stages, the S- and C-Band Communications System that is used for telemetry downlink, Flight Termination System receivers and equipment, a GPS beacon and a vehicle encoder.

Minotaur IV uses an improved telemetry system for real time data downlink up to 2Mbps with channels reserved for payload use.

Also mounted on the avionics ring is the Attitude Control System of the launcher which is a cold gas system using pressurized Nitrogen. The attitude control system is used for roll control during the 3rd, 4th and HAPS stage burns as well as three-axis control during coast phases and the Contamination and Collision avoidance maneuver.

The Common Avionics Assembly gathers navigation data using an inertial platform that feeds the digital autopilot of the vehicle. The three-axis autopilot is programmed to fly a pre-programmed attitude profile during Stages 1 and 2 flight and gather navigation data which is then used to optimize the trajectory during the Stage 3 and 4 (& HAPS) burns.

The two upper stages use a pre-defined set of parameters for their target trajectory which they use to modify their flight profile based on actual achieved trajectory by the lower stages.

The Orion 38 and Star 48 stages use energy management to achieve the insertion trajectory. After the final boost phase, the three-axis cold-gas attitude control system is used to orient the vehicle for spacecraft separation, contamination and collision avoidance and downrange downlink maneuvers.