Falcon 9 FT (Falcon 9 v1.2)

Falcon 9 FT represents an evolved version of SpaceX’s Falcon 9 v1.1 rocket incorporating a number of performance enhancements to enable the launch vehicle to lift heavy satellites to Geostationary Transfer Orbit while preserving the option of re-using the first stage. Operated by Space Exploration Technologies, the rocket represents the third evolutionary stage of the Falcon 9. The Falcon 9 Full Thrust (FT) vehicle is also known as ‘Falcon 9 Upgrade,’ ‘Enhanced Falcon 9,’ ‘Full Performance Falcon 9’ and ‘Falcon v1.2.’

The Falcon 9 FT launch vehicle is based on the Falcon 9 v1.1 (F9R) which in turn built on the original Falcon 9, retrospectively known as the v1.0 version of the rocket. Falcon 9 v1.0 was inaugurated in 2010 and flew successfully five times until 2013 when it was succeeded by the v1.1 version of the launcher. Falcon 9 v1.1 is retired after 15 missions, one of which was a failure. The v1.1 version itself was subject to a stepwise evolution, notably the implementation of reusability technologies on its first stage. These systems, among other changes, are standard on the Falcon 9 FT that premieres in late 2015 and is likely the final version of Falcon 9 with the maximum possible performance.

Falcon 9 is operated from Space Launch Complex 40 at Cape Canaveral Air Force Station, Florida, SLC-4E at Vandenberg Air Force Base in California and a launch site exclusively constructed and used by SpaceX, Boca Chica in Texas. The use of three launch sites allows Falcon 9 to target all orbital inclinations and to reach a launch rate unparalleled in the commercial launcher business.

Notable payloads lifted by the Falcon 9 fleet include the SpaceX Dragon spacecraft in its uncrewed version for cargo delivery missions to the International Space Station as well as crewed Dragon 2 flights to ISS. SpaceX holds a contract under NASA’s Commercial Resupply Services Program and the company has been selected to develop and operate a crewed version of Dragon as part of NASA’s Commercial Crew Program. Under the extended Commercial Resupply Services 1 contract, the Falcon 9 – Dragon Combination will perform a total of 15 resupply missions to ISS.

Falcon 9 was designed from the beginning to perform crewed launches with built-in robustness and redundancy. As part of Commercial Crew, Dragon aims to restore the United States’ human launch capability and deliver astronauts to the International Space Station. Falcon 9 will also launch DragonLab missions, but the bulk of launch business will occur on the Geostationary Communications Satellite market.

Falcon 9 Evolution

The Falcon 9 v1.0 version premiered in 2010 and made five flights including the first three Dragon missions to the International Space Station. An overview of the Falcon v1.0 can be found here.

Taking the v1.0 rocket and fully developed manufacturing techniques and components as a basis, SpaceX introduced the first major evolution of the Falcon 9 in 2013. Known as the v1.1 version, the launch vehicle represented a 60% increase in launch mass and liftoff thrust over the original vehicle design. The most notable changes introduced by the v1.1 version were stretched propellant tanks on both stages of the rocket, the introduction of the more powerful Merlin 1D engines replacing the previously used Merlin 1C engines, and a new thrust structure and engine arrangement switching from a tic-tac-toe design to an Octaweb arrangement.

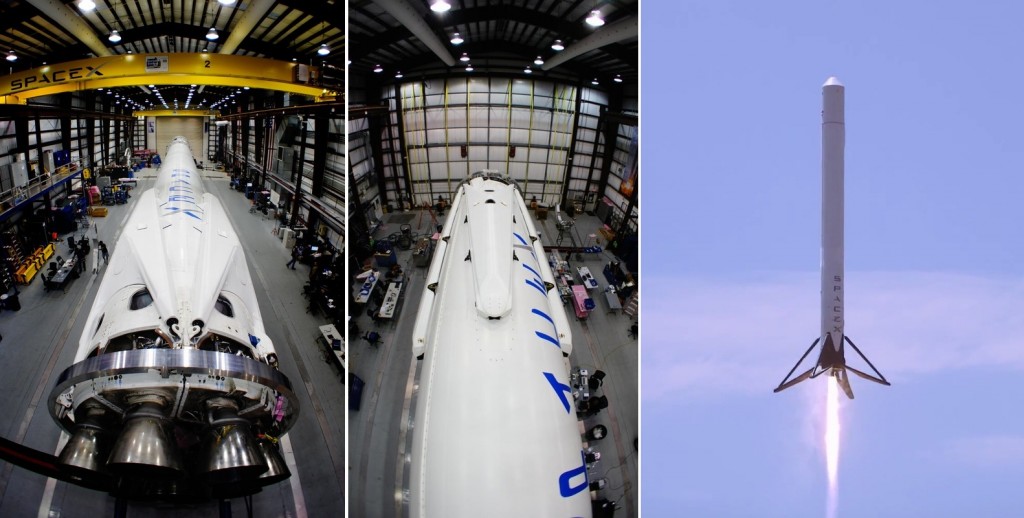

While Falcon 9 v1.1 was in operation, a stepwise evolution of the launcher continued with focus on the introduction of systems enabling the first stage to return to Earth for re-use. These technologies included the addition of four landing legs to the first stage, a more powerful cold gas reaction control system and four aerodynamic grid fins for guidance of the first stage during its return to Earth. Initially, Falcon 9 v1.1 first stages returned to a floating platform in the Ocean downrange from the launch site known as the Autonomous Spaceport Drone Ship. Stages of the Falcon 9 FT and the Falcon Heavy will return all the way to the launch site for a propulsive landing on concrete pads.

The upgrade from Falcon 9 v1.1 to the Full Thrust version is not as significant as the v1.0 to v1.1 transition in terms of visible changes on the launch vehicle. The goal of this latest evolutionary step of the Falcon 9 is to squeeze the maximum possible performance out of the launch vehicle and its engines to enable the launcher to carry heavy satellites to Geostationary Transfer Orbit while preserving enough propellants for the propulsive return to Earth for re-usability of the first stage that will significantly reduce the cost of future missions.

The most notable changes on the Full Thrust Version of Falcon 9 include the use of densified propellant on both stages, a change in tank sizes, a slight stretch of the interstage and second stage length, modifications in the thrust structure, weight-reduction measures and the operation of the Merlin 1D engine at its Full Thrust Stage. Falcon 9 v1.1 operated the engines well below their design specification.

Overall, the transition of Falcon 9 v1.1 to the FT version brings a 33% increase in performance, enabling the launcher to return its first stage on most missions involving heavy satellites headed to high-energy orbits.

Falcon 9 FT Specifications

| Type | Falcon 9 FT |

| Height | 70 m |

| Diameter | 3.66 m |

| Launch Mass | 549,054 kg |

| Stages | 2 |

| Boosters | None |

| Mass to LEO | 22,800 kg |

| Mass to GTO | 8,300 kg |

| Mass to Mars | 4,020 kg |

| Launch Cost | $62 M |

The Falcon 9 Full Thrust launch vehicle retains the overall design of the previous Falcon 9 rockets as a two-stage-to-orbit launch vehicle. Its first stage includes all systems necessary for an operational re-use of stages while the second stage is operated as an expendable rocket stage.

Falcon 9 FT stands 70 meters tall, is 3.66 meters in diameter and has a launch mass of 549,054 Kilograms. Both stages use sub-cooled Liquid Oxygen and chilled Rocket Propellant 1 as propellants consumed by Merlin 1D engines, nine of which are installed on the first stage while the second stage hosts a single Merlin 1D engine optimized for operation in vacuum.

SpaceX lists the payload capability of the Falcon 9 FT as 22,800 Kilograms to Low Earth Orbit and 8,300kg to Geostationary Transfer Orbit – these figures are for the fully expendable configuration of the vehicle. Leaving sufficient propellant margin for the return of the first stage to the Autonomous Spaceport Drone Ship for later re-use cuts the payload mass to GTO to around 5,500 Kilograms.

To achieve an operational re-usability of Falcon 9 first stages, all Falcon 9 FT rockets are outfitted with a reaction control system, four grid fins for steering and four deployable landing legs. Dropping the second stage off on its way to orbit, the first stage goes through a series of complex propulsive maneuvers before guiding itself through the atmosphere towards a target landing site for a soft touchdown under the power of one of its Merlin engines to be re-used on a future flight.

Merlin 1D Performance Enhancement

SpaceX is attempting to squeeze the most possible performance out of the Falcon 9 launch system without significant design changes to the launch vehicle itself. Increasing performance of the launcher leads to a greater payload capability or a greater margin for the propulsive return of the first stage, either to the launch site or the Autonomous Spaceport Drone Ship depending on the energy requirements of the specific mission.

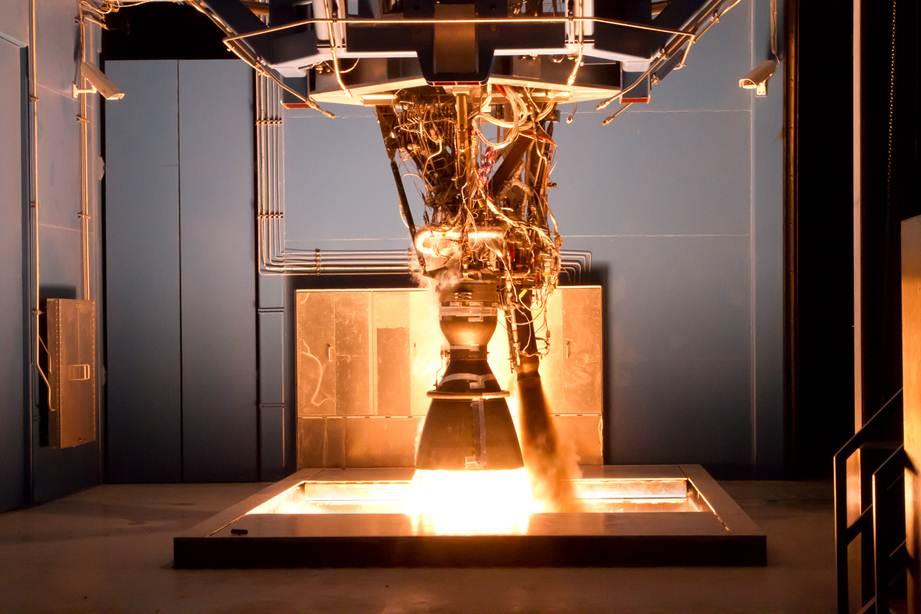

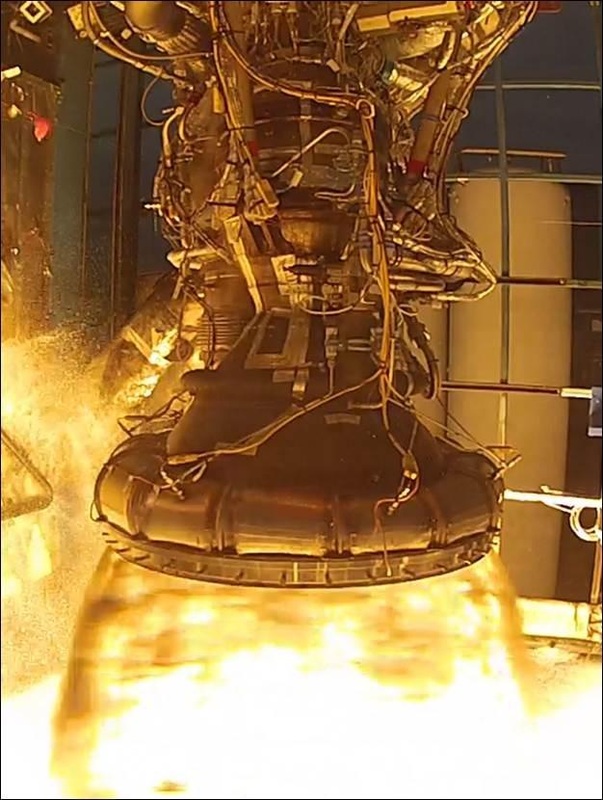

Using improved manufacturing techniques and materials, the Merlin 1D engine was developed with a great margin in operational conditions and a high degree of durability which would enable the engine to operate at higher thrust levels, pressures and temperatures than originally envisioned. In a 2013 press briefing, SpaceX CEO Elon Musk stated that Merlin 1D, at the time, was being operated at around 85% of its potential and work was underway to certify the Full Thrust setting of the engine for flight. Development and certification testing of the original Merlin 1D finished in mid-2012 and the engine flew for the first time in 2013. Testing of the engine at full thrust began afterwards followed by qualification testing in the summer of 2015.

Perhaps SpaceX was already looking toward Falcon Heavy when designing the Merlin 1D for operation at this increased thrust setting. Running the engine at a greater propellant mass flow rate will lead to a higher chamber pressure and chamber temperature, increasing the overall stress on the engine which has been accounted for in the initial design of the Merlin 1D.

A further increase in Merlin 1D thrust was revealed by Elon Musk in late April 2016. According to Musk, good performance of the engine in its first missions and delta-qualification testing will allow SpaceX to further raise the engine’s performance, currently expected at some point in 2016.

The latest numbers published on the performance of the Full Thrust version of the Merlin 1D engine specify a sea level thrust of 845 Kilonewtons, representing a 24% increase over the initial M1D version and an 11% over the first M1D+ running at 756kN. In vacuum conditions, the Merlin 1D+ engine delivers 914 Kilonewtons of thrust.

These numbers further cement Merlin 1D’s position as the most powerful engine ever built in terms of Thrust to Weight Ratio. The improved Merlin 1D Vacuum engine uses an extended nozzle design and achieves a thrust of 935 Kilonewtons, representing a 17% increase in thrust. (Additional specifications and details on the Merlin 1D engine can be found in the sections below.)

Using this engine on the Falcon 9 rocket leads to more launch thrust, but to accommodate the greater propellant mass flowrate and achieve the desired increase in performance, the rocket needs to launch with a greater propellant mass which can either be achieved by further expanding the tanks or densifying the propellants. Because the dimensions of the first stage of Falcon 9 was maxed out with the upgrade to the Falcon 9 v1.1, SpaceX decided to implement propellant densification.

Propellant Densification

To accommodate the more powerful Merlin 1D engines running at their full thrust setting, Falcon 9 employs propellant densification and a change in tank sizes to increase the mass of propellants it can hold. The performance gained by Falcon 9 FT arises from increasing the total propellant mass in both stages for an improved propellant mass fraction and a longer burn time.

Elon Musk stated that propellant densification capability would be added to all SpaceX launch facilities and all Falcon Heavy missions will rely on densification. Densifying propellants is possible through cooling – increasing the mass than can be loaded into the limited tank volume of the launcher.

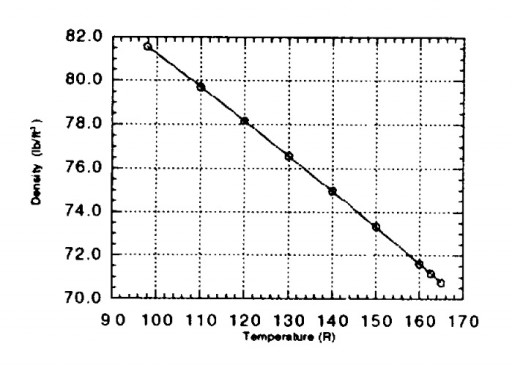

NASA studies have shown that LOX densification can increase the oxidizer mass by 8 to 15% compared to boiling-point LOX at –183°C.

Cooling LOX below its boiling point is possible through the use of a Nitrogen subcooler that employs a Liquid Nitrogen bath (either at boiling point or sub-cooled) through which the LOX lines are running to allow an exchange of heat.

SpaceX employs LOX at a temperature of approximately –207°C, about 10°C above the Oxygen Triple Point achieved by running the LOX through a Nitrogen bath that is kept at a partial vacuum to decrease its temperature to nearly N2 ice temperature. This will yield an increase in LOX density from 1.134 grams per cubic centimeter to nearly 1.23g/cm³ while still maintaining the LOX above its freezing point and slush density of 1.338g/cm³. Cooling the LOX to this temperature point yields a density increase of around 8%.

Operational launchers that employ sub-cooled LOX are Antares (in its original version, using LOX at –196°C) and Soyuz 2-1v (-192°C LOX), but in these cases, sub-cooled LOX is/was required due to the design of the engine.

Cooling the fuel, Rocket Propellant 1 (Kerosene), is also possible, although its high freezing temperature of approximately –37°C and changes in viscosity as a function of temperature represent limitations when cooling the fuel. SpaceX chills the RP-1 from ambient temperature down to approximately -7°C where viscosity does not yet affect the properties of the fuel, but achieves an increase in density around 2.5 to 4%. Calculations show that Falcon 9 consumes RP-1 at a density of 0.86g/cm³.

Because of the different densification possible for LOX and RP1, an adjustment of tank sizes on the rocket is necessary to keep the Oxidizer to Fuel ratio required by the Merlin 1D engines.

This is accomplished by shortening the LOX tank on the first stage and stretching the RP-1 tank while retaining the original first stage length. Stretching the first stage beyond the length of the v1.1 first stage is not possible due to bending forces occurring in flight. Widening the diameter of the stages is also no option because of the requirement of road transport, putting a limit on the maximum diameter. The second stage of Falcon 9 FT accommodates the required change in RP-1 volume by stretching the stage.

First Stage

| Type | Falcon 9 FT Stage 1 |

| Length | 42.6 m (47m w/ Interstage) |

| Diameter | 3.66 m |

| Inert Mass | ~22,200 kg (est.) |

| Propellant Mass | 411,000 kg (According to FAA) |

| Fuel | Rocket Propellant 1 |

| Oxidizer | Liquid Oxygen |

| LOX Mass | 287,430 kg |

| RP-1 Mass | 123,570 kg |

| LOX Volume | 234,700 l |

| RP-1 Volume | 143,900 l |

| LOX Tank | Monocoque |

| RP-1 Tank | Stringer & Ring Frame |

| Material | Aluminum-Lithium |

| Interstage Length | 4.5 m (est.) |

| Guidance | From 2nd Stage |

| Tank Pressurization | Heated Helium |

| Propulsion | 9 x Merlin 1D |

| Engine Arrangement | Octaweb |

The first stage of the Full Thrust version of the Falcon 9 is very similar to that of the Falcon 9 v1.1, only featuring minor differences such as the use of densified propellant, slight changes to the thrust structure and weight-reduction in the Octaweb structural design.

The first stage used for single-core Falcon 9 missions is identical to that of the boosters of the Falcon Heavy rocket, minus the attach points interfacing with the core stage. The Falcon Heavy core stage has a different design, utilizing a stronger thrust structure to accept the thrust force from the two boosters. Having the boosters of the Falcon Heavy and the core of the Falcon 9 FT sharing a design allows SpaceX to only manufacture two different stages, thus simplifying the need for tooling and streamlining the manufacturing process – an essential requirement when aiming for the launch rates SpaceX expects to reach.

The Falcon 9 FT first stage stands 42.6 meters tall and is 3.66 meters in diameter featuring the standard design with the oxidizer tank located above the fuel tank. Monocoque structure is utilized on the oxidizer tank while the fuel tank features a stringer and ring-frame design that adds strength to the vehicle.

All components of Falcon 9 and Falcon Heavy are designed with structural safety margins 40% above the expected flight loads, higher than the 25% margin that has become the standard in the industry.

The first stage tank walls and domes are made from aluminum lithium alloy and make use of reliable welding techniques to provide maximum strength. The first stage consumes Liquid Oxygen oxidizer and Rocket Propellant-1 as fuel which is highly refined Kerosene. The LOX feedline is routed through the center of the fuel tank to supply oxidizer to the engines fed through 10-centimeter lines until reaching a 9-way manifold that distributes propellants to the engines.

Falcon 9 FT uses sub-cooled Liquid Oxygen and chilled Rocket Propellant 1 to increase the mass of propellants that can be held in the tanks. Based on the design of Falcon 9 v1.1 and the known propellant temperatures, the propellant capacity of the Falcon 9 FT first stage can be estimated. Calculations show the first stage is capable of holding 123,600 Kilograms of Rocket Propellant 1 and 287,500kg of Liquid Oxygen. The empty mass of the first stage is not known, but is likely similar to that of the Falcon 9 v1.1 at around 20 to 24 metric tons.

Falcon 9 FT sports nine Merlin 1D engines running at their Full Thrust setting, sometimes referred to as M1D+. Merlin 1D uses improved manufacturing and quality control techniques to enable SpaceX to produce a greater number of engines per year while reducing overall risk. The M1D design is simplified over the M1C by removing no-longer-needed subassemblies and cutting the number of engine parts.

Electro-plating of a nickel-cobalt alloy on the chamber to create the jacket that endures the primary stress of the pressure vessel was replaced by using an explosively formed metal jacket. These changes provide the Merlin 1D with an increased fatigue life and greater thermal margins for the chamber and nozzle.

| Engine | Merlin 1D Full Thrust |

| Engine Type | Gas Generator, Open-Cycle |

| Propellant Feed | Turbopump |

| Merlin 1 D Thrust | Sea Level: 845 kN – Vac: 914 kN |

| Engine Diameter | ~1.0 m |

| Engine Dry Weight | 470 kg |

| Burn Time | 162s |

| Specific Impulse | 282s (SL) 311s (Vac) (M1D Standard) |

| Chamber Pressure | >100 bar |

| Expansion Ratio | 16 |

| Throttle Capability | 55%-100% (Baseline, Possibly Deeper) |

| Restart Capability | Yes (Partial) |

| Ignition | TEA-TEB |

| Attitude Control | Gimbaled Engines (pitch, yaw, roll) |

| Cold Gas Nitrogen RCS | |

| 4 Grid Fins | |

| Shutdown | Commanded Shutdown |

| Stage Separation | Pneumatically actuated |

| mechanical collets |

Merlin 1D is an open-cycle gas generator engine. The gas generator operates fuel-rich, burning a small fraction of the LOX and RP-1 flow from the turbopumps to generate a hot high-pressure gas that drives a single turbine with the two turbopumps being driven by a one shaft. High-pressure RP-1 from the fuel turbopump is used in the hydraulic actuators that gimbal the nine main engines for thrust vector control. Generator gas flows through a heat exchanger which heats up Helium gas for tank pressurization in flight. The generator gas is then dumped overboard through an exhaust.

The Kerosene flow from the pump is directed to the combustion chamber and nozzle where it passes through heat exchangers as part of the regenerative cooling scheme of the engine. After passing through the heat exchangers, the fuel is pumped into the combustion chamber where it comes into contact with the oxidizer.

Merlin 1D+ operates at a high chamber pressure of over 110bar to generate a sea level thrust of up to 845 Kilonewtons (86,200kgf) and a vacuum thrust of 914kN (93,200kgf) – giving Falcon 9 FT a total liftoff thrust of 7,607kN (775,700kgf).

In the initial Falcon 9 FT version (2015/16), Merlin 1D is operated at a sea level thrust of 756kN and a vacuum thrust of 825kN. The throttle setting on the engine will be raised in 2016 based on the performance of the launcher in its initial missions and delta-qualification testing conducted with the revised performance parameters.

The engine has an increased expansion ratio of 16 while the M1C engine had an expansion ratio of 14.5. At a mass of 470 Kilograms, Merlin 1D achieves a thrust to weight ratio of 198 – the highest thrust-to-weight ratio in the liquid-fueled engine world. Merlin 1D uses a pyrophoric mixture of Triethylaluminium-Triethylborane (TEA-TEB) as igniter which is injected into the gas generator and combustion chamber to initiate the combustion process that is sustained as LOX and RP-1 flows into the GG/Chamber once turbopumps spin up, initially using high-pressure helium for spin-up.

Also, the engine has a deep throttling capability which allows Falcon 9 FT to fly a more flexible mission profile. The baselined throttle capability ranges from 55 to 100% of rated performance, however, there are strong indications that M1D may be able to throttle even deeper, possibly to 30%. Merlin 1C had no throttle capability and Falcon 9 v1.0 had to shut two Merlin engines down to limit stress on the vehicle as the launcher approached first stage cutoff.

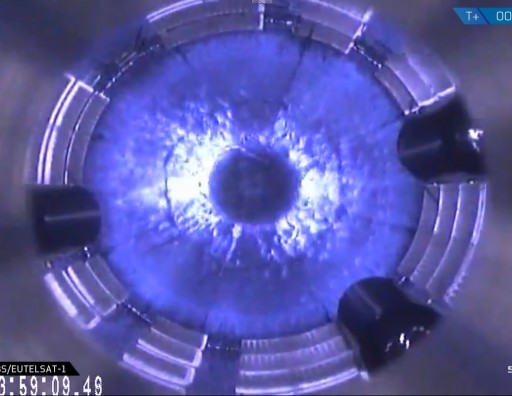

Falcon 9 FT, like the v1.1 version, employs an Octaweb engine arrangement. Eight engines are arranged in a circle – clustered around a single Merlin 1D in the center that is installed slightly lower with its nozzle protruding the others. The gas generator exhaust pipes of the individual engines installed on the perimeter of the first stage are arranged toward the inboard direction, their flow passing through the gap between the center and the outer engines, transporting excess heat out of the engine compartment.

The skin of the launcher is the primary load path for the launch vehicle and arranging most of the engines on the perimeter of the skin eliminates a lot of structure that needs to be installed to carry loads from the engines to the skin. The original tic-tac-toe engine pattern required these load-transferring structures, adding to the overall mass of the vehicle. The new engine arrangement also improves thermal properties as it avoids hot spots. Falcon 9 FT introduces even more improvements in the Octaweb structure, reducing weight which adds to the performance boost of the rocket.

With its greater thrust, the Falcon 9 FT launcher provides more flexible engine-out capability for a large portion of its first stage flight. All nine engines are ignited on the ground, about three seconds before launch and all must reach operational conditions and liftoff thrust for the launch release command to be issued.

The engines are monitored constantly in flight and computers can shut down any engine at any time to prevent RUD (rapid unplanned disassembly). Following the unplanned shutdown of an engine, the flight computer would re-plan the ascent trajectory to reach the cutoff target with the remaining engines by extending their burn.

Flying nine Merlin engines on the first stage provides engine-out capability and it also allows Merlin 1D to quickly build up flight heritage as each mission provides performance data on nine engines instead of a single engine that competing launchers are using.

The first stage is equipped with a cold-gas Reaction Control System using Nitrogen as propellant for three-axis control during coast phases and for roll control during single-engine burns. The ACS is installed on top of the first stage, allowing the thrusters to be utilized when pitching the stage for its re-entry maneuvers (see Re-Usability below).

The Falcon 9 first stage employs an S-Band communications system to transmit 3,000 channels of performance telemetry throughout the flight and after stage separation. The stage is equipped with a Flight Termination System consisting of two strings of transmitters, receivers and safe and arm devices. The FTS works with C-Band Communications and can be used to terminate the flight in case of any major anomalies. Falcon 9 has autonomous flight termination capabilities triggered by significant systems damage, most likely employing a break-wire type system. Flight termination is accomplished by splitting open the propellant tanks of the vehicle, rendering the rocket non-propulsive.

The first stage has a primary burn time that varies depending on the mission design. Flights using the full performance of the first stage without propulsive return maneuvers burn the first stage for up to 195 seconds while missions that include a first stage return require the stage to shut down its engines after 150 to 170 seconds of powered flight to leave sufficient propellants for the descent to a landing site.

The first stage is equipped with a triple-redundant flight control system as well as a navigation platform using GPS and Inertial Measurement Units to be used during flight in cooperation with the main flight computer on the second stage and as the vehicle’s only controller during the descent towards the landing site.

The first stage of the Falcon 9 is connected to the second stage via a carbon fiber aluminum core composite structure acting as interstage adapter, housing the MVac engine of the second stage as well as first stage hydraulics equipment for the Grid Fin System and the cold gas attitude control system. The interstage has to carry the entire weight of the second stage and spacecraft. Stage separation is accomplished via separation collets and pneumatic pushers in four interfaces connecting the two stages. SpaceX tries to avoid using pyrotechnics for separation events. A fourth pusher interface was added as part of the Falcon 9 FT upgrade to make the separation between stages more reliable.

First Stage Re-Use

The overall goal of SpaceX is to make the first stage of Falcon 9 (and the three cores of Falcon Heavy) fully re-usable by returning them to a landing site through a series of complex maneuvers performed after separation from the launcher using a small portion of leftover propellant. To rapidly re-use the first stage of the vehicle, Falcon 9 is ultimately planned to fly the stage back to the launch site after separation and land it vertically on deployable landing legs. Initial attempts of demonstrating the return flight were made by soft-landing stages in the ocean before upgrading to landing the first stage boosters on a floating platform.

The re-usable version of Falcon 9 does not represent a fully different launcher and started out as an add-on to the v1.1 version in the form of the Nitrogen Cold Gas Attitude Control System, the four deployable landing legs and four grid fins used for three-axis control during atmospheric flight, especially during non-propulsive flight phases. These systems are now standard on all Falcon 9 FT vehicles.

The overall design driver for the landing legs was mass since adding significant weight to the first stage would have resulted in a significant payload penalty. Safety was also a major concern – the leg design had to be such that no premature deployment during powered ascent was possible which would result in a certain loss of the entire vehicle and payload. Made of aluminum honeycomb and carbon-composite materials, the four legs have a total mass of around 2,100 Kilograms consisting of a single-load bearing strut and aerodynamic fairing assembly. The central struts of the legs interface with the load-carrying structure of the first stage while the fairings have two structural interfaces at the base of the engine compartment heat shield and one interface on the lower portion of the leg.

Falcon 9 FT has improved landing legs that can be opened earlier and so provide some additional aerodynamic stability in the final stages of the descent. During flight, the legs are stowed against the rocket body, covered by the fairings that ensure no additional aerodynamic disturbance is introduced by the legs. Deployment is accomplished by a pneumatic system using high-pressure helium. When deployed, the legs have a span of about 18 meters, capable of supporting the forces of landing and the mass of the nearly empty first stage.

Leg deployment occurs in the late stages of the descent to the landing site, during the landing burn. When deployed, the legs provide additional aerodynamic stability. For Falcon 9 FT, the design of the legs has been modified to support an early deployment to allow the additional drag from the legs to contribute to the deceleration of the booster on its way to a soft landing.

The four grid fins are launched in a position stowed against the uppermost section of the first stage near the interstage before being deployed when Falcon 9 re-enters the atmosphere. A slight modification of the grid design is part of the F9 FT upgrade. The four fins can be individually controlled in a two-degree of freedom type design, rotating and tilting at the same time, allowing for complex guidance and control during atmospheric flight.

The fins are an essential part of Falcon’s return sequence to provide control in atmospheric flight without active propulsion. Grid-fins have been widely used as a stabilizer on missiles & bombs and are shaped like miniature wings consisting of a lattice structure. The Russian Soyuz employs grid-fins in its launch abort system which would deploy when the launch escape rockets start firing in an abort scenario to stabilize the vehicle, but the fins used by SpaceX take it one step further as they can be moved independently to actively control the vehicle’s flight and not only act as a stabilizer.

Grid-fins perform well in all velocity ranges including supersonic and subsonic speeds with the exception of the trans-sonic regime due to the shock wave enveloping the grid. These properties make them ideally suitable for the Falcon 9 first stage that starts out at supersonic speeds and returns to subsonic velocity as it travels through the atmosphere, en-route to the landing site. The four fins are rotated and tilted independently by an open hydraulic system using pressurized hydraulic fluid supplied from a pressurized tank that is dumped overboard after flowing through the hydraulic actuators of the fin system. The design was also driven by overall mass considerations.

The addition of the grid fins was expected to improve the accuracy of Falcon’s landing by three orders of magnitude – previous landing attempts in the ocean had a ten-Kilometer targeting accuracy while the return to a platform or a pad on land requires the stage to land within a few meters of its bulls-eye target.

Before attempting to land first stages on land, SpaceX commissioned a floating platform that can be deployed in the ocean, downrange from the launch site to provide a landing pad for the first stage boosters.

Known as the Autonomous Spaceport Drone Ship, the floating landing platform was built at a Louisiana shipyard and measures 91 meters by 52 meters with a prominent Space“X marks the Spot” logo in the center. The ship sports four diesel-powered azimuth thrusters – similar to those on oil rigs – provided by Thrustmaster, a marine equipment manufacturer that also provided power modules and controls to outfit the ship with a Portable Dynamic Positioning System. Processing GPS data, the Autonomous Spaceport Drone Ship will be able to keep its assigned position with an impressive accuracy of three meters.

A high accuracy is required since Falcon 9 will have to land on the platform with all four of its legs that span approximately 18 meters, leaving just over 30 meters for GPS errors between the two craft and position errors of the drone ship, sea swell as well as errors by Falcon 9, making its fast-paced hoverslam landing under the power of one of its nine Merlin 1D engines with a thrust to weight ratio greater than one.

The ASDS is outfitted with a water deluge system that dumps water onto the deck to protect it from the heat of the engine of the arriving booster. Numerous attachment fixtures are part of the deck structure that would allow the securing of the first stage after landing on the platform.

The return flight of the first stage booster starts at the moment of separation from the Falcon 9 second stage that is delivered to a trajectory from where it can boost the payload into its desired orbit. First stage burn duration in missions that include a propulsive return is on the order of 165 seconds.

Separating the second stage at about 80km in altitude at a speed of Mach 10, the first stage heads on to an apogee altitude of around 140 Kilometers. Initially, the first stage uses its cold gas thrusters for attitude control – starting with a maneuver to depart the engine plume of the second stage before re-orienting to an engines-first position that is maintained past the point of apogee.

Around T+4.5 minutes into the mission, the first stage re-lights a subset of its engines for a boost-back maneuver that slows the vehicle down (or reverses its travel direction) and controls the downrange travel distance of the stage, beginning to target the planned landing site – either on land or in the ocean. The duration of the boost-back burn depends on the target landing site and is also driven by propellant availability for the return which varies depending on payload mass and insertion orbit.

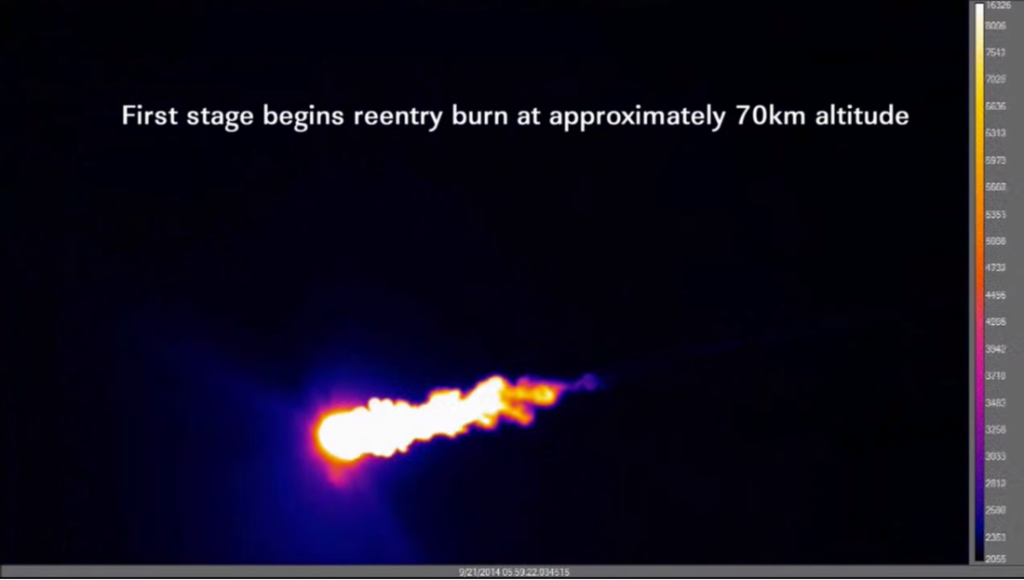

Heading back into the dense layers of the atmosphere, the first stage completes its supersonic retro propulsion burn using three engines that are fired for about 20 seconds starting at an altitude of 70 Kilometers. This burn in combination with drag in the atmosphere slows the first stage down from 1,300m/s to about 250m/s.

The first stage aft section has been outfitted with shielding material to be able to withstand the re-entry environment and, during atmospheric flight, the stage can maintain an engine-forward position by its low center of gravity caused by the heavy engine compartment in the aft.

Beginning at re-entry, the first stage starts using its four grid fins for roll, pitch and yaw control, especially during periods of flight when the engines are not running. Covering the final 40 Kilometers to landing, the booster uses its grid fins to maintain a pitch-trim to continue refining the course towards the landing platform while maintaining stable yaw and roll rates.

Homing in on its landing spot, the first stage ignites its center engine to begin slowing down to a landing speed of just about two meters per second and make the final cross-track and range adjustments to land on the platform. Ten seconds into the landing burn, the four landing legs are deployed to put the stage into its final landing configuration with touchdown just a few seconds later.

Second Stage

| Type | Falcon 9 FT Stage 2 |

| Length | 12.6m (Separated Length) |

| Diameter | 3.66 m |

| Inert Mass | 4,000 kg (est.) |

| Propellant Mass | 107,500 kg (est.) |

| Fuel | Rocket Propellant 1 |

| Oxidizer | Liquid Oxygen |

| LOX Mass | 75,200 kg (est.) |

| RP-1 Mass | 32,300 kg (est.) |

| LOX Tank | Monocoque |

| RP-1 Tank | Monocoque |

| Material | Aluminum-Lithium |

| Guidance | Inertial |

| Tank Pressurization | Heated Helium |

| Propulsion | 1 x Merlin 1D Vac |

| Engine Type | Gas Generator |

| Propellant Feed | Turbopump |

| Thrust | 934kN |

| Engine Dry Weight | ~490kg |

| Burn Time | 397 s |

| Specific Impulse | 348s |

| Chamber Pressure | >9.7MPa (M1D Standard) |

| Expansion Ratio | 165 |

| Throttle Capability | Yes |

| Restart Capability | Yes |

| Ignition | TEA-TEB, Redundant |

| Pitch, Yaw Control | Gimbaled Engine |

| Roll Control | Reaction Control System |

| Shutdown | Commanded Shutdown |

| Reaction Control S. | Cold-Gas Nitrogen Thrusters |

The second stage of the Falcon 9 FT is based on the design of the v1.1 second stage, but is stretched by around half a meter to accommodate additional propellant. This is done to increase the performance of the second stage which will have to do more work getting a payload into orbit in order to ease the process of returning the first stage core.

The second stage shares its diameter with the first stage and a similar architecture and tank structures with identical construction of tank domes and walls. SpaceX has always followed a policy of choosing simple solutions to reduce cost and risk in order to manufacture a robust launch system. Using the same materials, tools and manufacturing techniques for the two stages is a perfect example of that policy.

The tanks are built using Aluminum-Lithium Monocoque structure for both tanks.

As with the first stage, the exact dimensions of the second stage have not been disclosed by SpaceX. The second stage matches the first stage’s diameter of 3.66 meters. The stage is approximately 12.6 meters in length without payload adapter and 1st Stage Interstage with an inert mass of around four metric tons. The second stage can hold approximately 75,200kg of LOX and 32,300kg of RP-1 giving it a launch mass of ~111,500kg.

Sub-cooled LOX and chilled Rocket Propellant 1 are also used by the second stage. The difference in densification of LOX and RP-1 requires the Falcon 9 v1.1 second stage RP-1 tank to be stretched in order to keep up the Ox. to Fuel ratio required by the engine.

One Merlin 1D Vac engine is powering the second stage, also operating at its full thrust setting. This engine differs from the first stage engines as it is optimized for operation in vacuum featuring an extended nozzle with a high expansion ratio. Compared to the original M1D design, the M1D+ Vac has an even longer nozzle. It also is a turbopump-fed gas generator engine, operating at a chamber pressure of over 110 bar.

Using an extended nozzle creates a high expansion ratio of 165:1. M1D Vac has a high specific impulse of 348 seconds and generates a total vacuum thrust of 934 Kilonewtons (95,240 Kilogram-force). The engine can support multiple ignitions to be able to fly a flexible mission profile in order to reach a variety of orbits and trajectories. The second stage TEA-TEB ignition system is fully redundant.

The second stage is equipped with a Reaction Control System for three axis-control during coast phases and roll control during burns. The Falcon 9 FT uses a cold-gas attitude control system employing a number of Nitrogen thrusters that can support extended mission durations to high-energy trajectories.

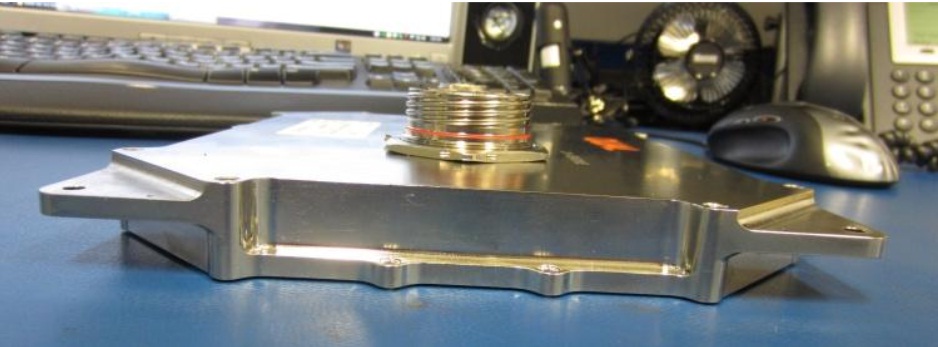

The second stage of the Falcon 9 rocket facilitates the avionics and flight computers that control all aspects of the flight. The avionics of the Falcon 9 feature a number of changes and upgrades from the v1.0 to the v1.1/FT version. All avionics and controllers are manufactured in-house by SpaceX. The system is fully redundant, constantly checking itself to verify that all GNC components are functioning properly. SpaceX uses commercial off-the-shelf parts that are radiation tolerant instead of radiation hardened (cost reduction). The flight computers run on Linux with software written in C++.

Avionics are triple redundant and the rocket’s inertial navigation system uses GPS overlay for additional orbital insertion accuracy.

In addition to the main avionics units of the launch vehicle, each of the Merlin Engines is equipped with three processing units in a single engine controller. The engine controller monitors all parameters of the engine and interfaces with the main avionics units. Each of the three processing units are constantly checking on the others to provide fault-tolerance.

Payload Fairing

| Payload Fairing | Composite Fairing |

| Diameter | 5.2m |

| Length | 13.1m |

| Weight | ~1,750kg |

The Payload Fairing is positioned on top of the stacked vehicle and its integrated spacecraft. It protects the vehicle against aerodynamic, thermal and acoustic environments that the launcher experiences during atmospheric flight. When the launcher has left the atmosphere, the fairing is jettisoned. Separating the fairing as early as possible increases ascent performance.

Falcon 9’s standard Fairing is 13.1 meters in length and 5.2 meters in diameter. The fairing consists of an aluminum honeycomb core with carbon-fiber face sheets fabricated in two half-shells. Separation is accomplished via a pneumatic system along the vertical seam that pushes the two halves apart.

Up to three spacecraft access doors or Radio Frequency Windows can be supported by the fairing. A small 3.6-meter fairing is also being developed.

Payload Adapters

Payload Adapters interface with the vehicle and the payload and are the only attachment point of the payload on the Launcher. They house equipment that is needed for Spacecraft Separation and ensure that the payload is secured during powered flight. Electrical and Communication connections are also part of the Adapter and route spacecraft Telemetry to the Flight Computers for downlink. A variety of different adapters is available to suite different spacecraft needs and requirements.